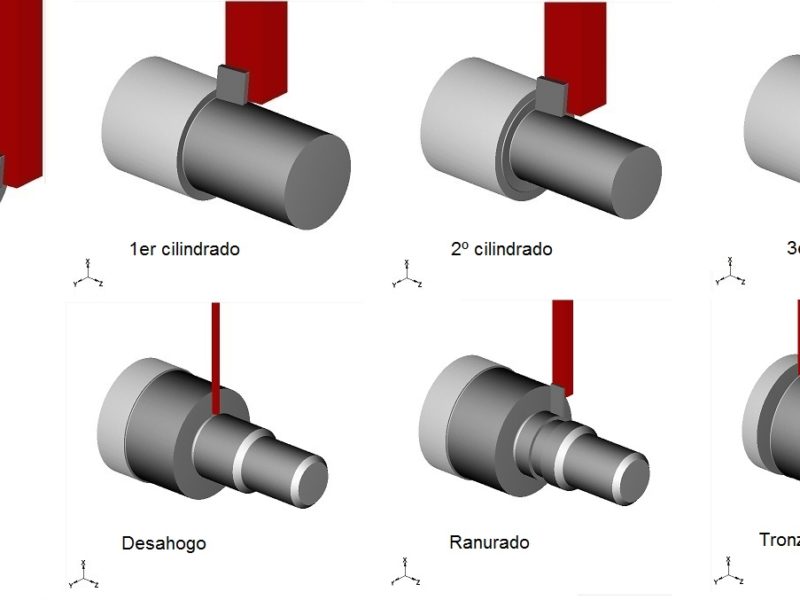

We highlight the main turning operations for both CNC and conventional lathe

What’s a lathe?

The lathe is one of the most used machine for metal and wood cylindrical parts production. The process is by revolution of the part, the tool remains static (except in the Motorized tool CNC lathe). The part is clamped to the chuck remaining flown for short parts or supported by a follow or steady rest and a tail stock when the parts are longer and stability is required in order to avoid vibrations and unaccurate results.

Most of main turning operations are:

- Contour turning: Para rebajar el diámetro de la pieza.

- Taper turning: Grant conicity to the piece.

- Contour turning: To shape part of the cylinder.

- Chamfering: Cutting or recessing of an edge of the solid body.

- Cut off: Depth turning until the complete cut of the piece.

- Threading: Considering the thread requirements like the pitch, to thread the part in the inside or outside face.

- Drilling: Make a hole inside the part

- Boring: To increase a inner hole.

- Knurling: Facing the front side of the part to reduce its length or clean it.

Our range of parallel:

Recent Comments