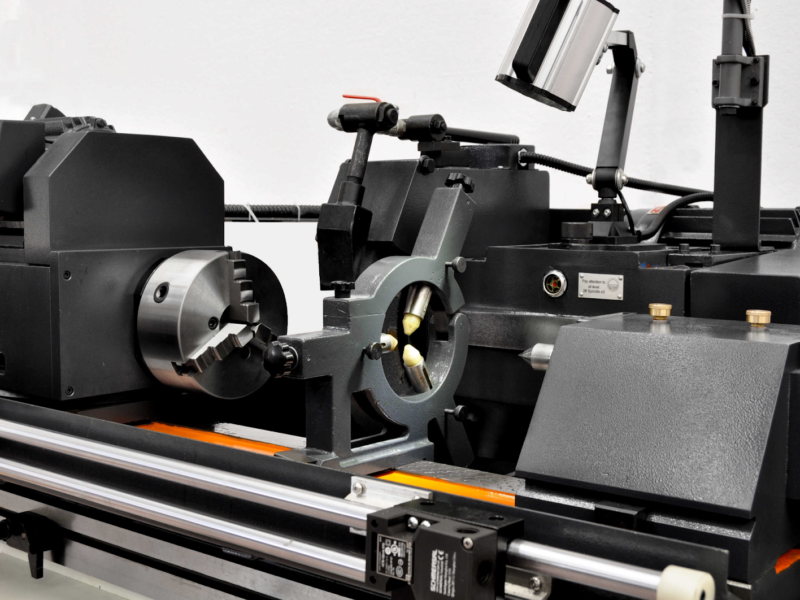

The cylindrical grinding machine is a machine tool that is used for machining by abrasion; that is, through the wear of the surface of the piece using abrasive substances and elements . One of these tools that allow parts to be machined by this method is the grinding wheel that is placed on cylindrical grinding machines.

Machining on a cylindrical grinding machine

In cylindrical grinding machines, abrasion machining is carried out on pieces with very specific measurements and tolerances. The characteristic of grinding is that it is a process that is carried out after other machining such as turning, milling or drilling. Grinding is a process to complete the design of a piece; Through this work, the piece is given its final finish.

For grinding it is necessary to have specific machines equipped with the tools required for this abrasive procedure. It is for this reason that a cylindrical grinding machine is made up, among other parts, of a bed with a solid structure and equipped with two heads that are mounted on carriages.

On the one hand there is the carrier of the grinding wheel or abrasive wheel and which is usually fixed and, on the other, the carrier of the driving wheel, it is generally collapsible.

Cylindrical grinding machine type

These machines, which can work in different ways, are divided into three:

- External: used for grinding the external surfaces of parts between centers. The part can rotate and the grinding wheel rotates in the same direction as the part when it comes into contact with it.

- Internal: in these machines grinding is done on the internal part of the piece. The grinding wheel is smaller than the width of the piece, which is attached to a magnetic ring that prevents it from moving.

- Centerless: that allow grinding of small parts. This type of cylindrical grinding machine has two grinding wheels that rotate in the same direction; a piece that rotates in the opposite direction to the grinding wheels is placed in the space between them.

What is grinding wheel?

The grinding wheel is a fundamental piece in the cylindrical grinding machine, as it is an abrasive tool that allows the removal of tiny chips in abrasive machining. In this type of process, materials with a high degree of hardness are used that are capable of eliminating small amounts of chips, which allows to work complex pieces and of reduced dimensions.

Abrasion machining is used on hard and complex materialsthat are difficult to remove by other methods such as turning or milling.

Features

Any wheel is not valid for a cylindrical grinding machine. That is why it is important, before getting hold of this tool, to know the characteristics and properties that it must have to do the job properly:

- The grinding wheel has an indefinite number of cutting edges made up of abrasive grains. These grains, which are joined by a binder, allow the removal of small amounts of material.

- The cutting points of this tool are located randomly.

- They have a < strong>cutting speed that reaches 4000 m/min.

- The material removal speed is 300 mm/min.

- The grinding wheel consumes 10% of the energy used in this process.

- The chips generated are millimetric.

Abrasive and binder

The most important thing about a cylindrical grinding wheel is the materials that make it up, such as the abrasive and the binder.

The abrasive has the function of removing the material and its parameter is the size of the grain with respect to the imprint that will remain on the surface of the piece. If the abrasive grain is large, the removal rate will be higher, but the part will have a rough finish. For roughing operations, coarse-grained wheels are used, while fine-grained wheels are used for finishing operations on the cylindrical grinding machine.

All grits must be the same size, resistant to wear, and hard enough to apply to hard materials.

The binder, meanwhile, keeps the grains together during machining. This material has the characteristic of preserving the state of the abrasive despite the cutting efforts, the speed, the force used and the heat generated.

Placing and movements of the grinding wheel in the cylindrical grinding machine

To correctly place a wheel on the cylindrical grinding machineit is necessary to carry out certain operations prior to machining. Once the grinding wheel has been mounted, following the manufacturer’s instructions, it is important to balance the tool and hold it correctly on the shaft. If this is not done properly, the grinding wheel will not be able to do the job as it should and the results will not be as desired; in addition, it is possible that the part wears faster than normal.

The grinding wheel follows three types of movement in the cylindrical grinding machine:

- Rotation of the feed wheel, which in turn generates the advance movement towards the piece. It is a slow movement.

- Cut: it is a movement independent of the rotation.

Angle: This is the inclination that can be given to the drag roller. This movement generates the axial displacement of the part.

Recent Comments